Just click on a question to get your answer!

Can't find what you're looking for? Give us a ring on 0113 512 0398

In dry conditions this surface is suitable but when wet and especially in icy conditions then the answer is NO. In winter months PIC should be travelled over carefully.

Yes; block paving is the easiest hardstanding to repair. If it's one of ours please contant us for any repairs if it needs to be dug up at any point. If reinstated by a third party and it failed it would void the warranty.

The problem is not with jet washing. Infact, that is the best way to maintain block paving! It is about using the right attachment on the jet washer itself.

If you use a standard jet wash that shoots water through a straight jet then the water will be forced all the way down the sides of the blocks and potentially displace the grit sand under the blocks leading to distorted blocks once trafficked. Professional flat surface cleaners are designed with jets that shoot water at a 45% angle and are designed to remove only the top 15-20mm of the surface between the blocks below the surface. This way of cleaning is important to a long lasting trouble free block paving driveway.

No, certainly not. Like any driveway the wearing course is only as good as the sub base. It’s paramount when installing a block driveway that the correct specification on base courses is adhered too. Even with the right type and depth of base coats will fail if not properly compacted. A walk behind vibrating plate is not enough for any base courses . Ideally a large ride on vibrating roller on large areas or heavy diesel forward/reverse walk behind compactors on smaller areas.

All our driveways are done to specification using a quality type 1 hardcore base, so a gravel base course would also lend its self to other hard standing driveways like tarmac or PIC. These surfaces could be laid over the existing base once the gravel has been removed. Only resin bound is the exception as it needs a specialised type 3 base course.

Unfortunately when doing any ground work to a good and correct specification there is no such thing as a cheap job. Gravel driveways still need to be excavated and a correct sub base with supporting edges fitted. The savings to be had with a gravel drive comes from the lower cost of the gravel material and the ease of installation.If you were to just scrape the grass off and cover with gravel then you would certainly save money in the short term but would be left mess further down the line.

When installing a gravel driveway, slightly raised edges should be created using blocks, pin kerbs or sometimes timber edging if the design suits so that the loose stone will not easily be pushed into surrounding areas. Also be sure to go easy when accelerating in vehicles as to not cause the wheels to spin and the gravel to be displaced.

Yes Indian stone should be sealed with a good quality sealer to prevent staining. Make sure all lichen and efflorescence is totally removed before sealing, if you seal over the staining, chemicals and jet washing will have no effect.

Natural stone and manufactured stone both suffer from lichen and efflorescence, this is described as black staining or spotting and can be removed by combining jet washing with chemical agents.

Indian stone flagstones can be used but with the surface area of each flagstone being so large it is sometimes difficult to follow the curvature of the land. A small style of Indian stone cobble/block pavior is better suited to driveways.

Yes; with the development of sealers and additives there are now really effective anti slip systems that can be added to your finished surface. This for us is a must and is always factored in the final cost.

Some PIC patterns offer more natural grip due to design than others . It’s worth taking this into consideration when making your selection.

We only provide estimates online and we would need to do a site survey to confirm the details and create a final quotation. The more time our clients spend creating their online estimate, the more accurate the final quotation will be.

Yes; tarmac can be repaired but the repair would be visible. If the area is small it sometimes warrants to take off the whole area of tarmac topping and relay the entire wearing/surface course. This can also be done every 20 years or as necessary making a tarmac driveway a really cost effective lifetime option for a driveway.

Tarmac is very hard wearing but should be used properly in order not to cause damage due to excessive wear or misuse. Dry turning vehicles or point loading with heavy or sharp edges should be avoided or kept to a minimum.

No; properly installed tarmac driveways should never dip or sag under vehicle pressure. The most common cause is bad or incorrect sub base and base coats.

NO, not in any circumstances. If drainage is an issue on overlay systems then correct drain ducts and channels should be installed. Drilling holes in sound surfaces leads to all kinds of problems and is considered bad practice.

The water will still pass through the resin giving the benefit of no puddles or surface water, but the water will still run off under the resin as with the natural fall of the land. The water will pool in areas as it did before the resin it will just not be visible. It will dry and evaporate as usual.

Yes, Resin Bound when installed over the properly specified sub base is fully porous and conforms with the SUDS regulations for permeable surfaces.

No, not at all. All our advice and quotations are free and you are never obligated or put under pressure to go ahead with the work. Only when you are ready to commit to the work will we create a job file and get the ball rolling.

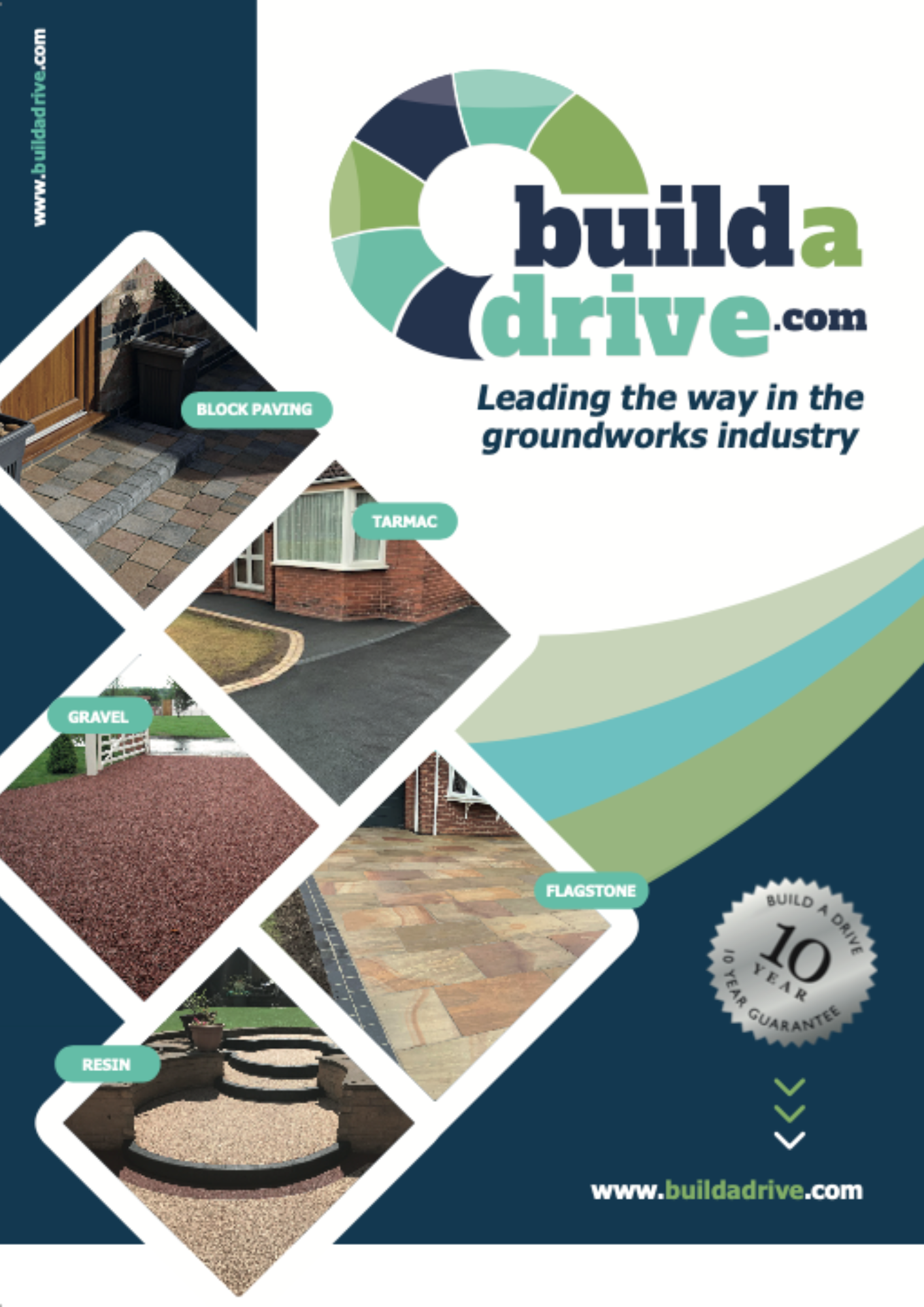

All of our hard standings come with a 10 year warranty. It’s worth reading about your chosen surface on our surfaces page to make sure you understand the pros and cons for that particular surface.

That’s easy to explain. We have coverage charts for each product and material, eg 1 tonne of type x hardcore laid @ 150mm depth will cover 3sqm, so a 30 SQM driveway would require 10 tonne. That rule of thumb works for all materials if you know the coverage rates.